You are at the Most Professional Blender Manufacturer and Supplier – China Factory

Production capacity and experience

SINREEN has been committed to the production of blenders for more than 10 years. It is equipped with 13 production lines, and each production line has the capacity to produce the equivalent of one 40HQ – cube container’s worth of products per day.

Strict quality control

For blenders produced by SINREEN, the defect rate in 2023 is a mere 1‰. The high – quality blenders are ensured through stringent inspections during the production process and comprehensive pre – shipment spot – checks. Thanks to these rigorous checks, the defect rate of SINREEN’s blenders stays extremely low, only 2‰ in 2023.

Flexible cooperation model

Whether brand owners look for full – brand customization of blenders or wholesalers make mixed purchases of different models, SINREEN can offer suitable solutions and provide experience support. Committed to fulfilling diverse requirements for blenders, SINREEN has the expertise and resources to create tailored solutions.

Contact Us

Filling out the form will not invade your privacy, so please feel free to do so.

You are at the Most Professional Blender Manufacturer and Supplier – China Factory

SINREEN Best Electric kettle

3 in 1 Glass Knob Blender

1.4L 250W 3 in 1 Glass plastic Juicer Knob Blender

Button plastic 2 in 1 Blnder

1.8L 250W 6 speed Juicer button cheap discount Blender

Grinding 3 in 1 meat grinder knob Blnder

1.6L 300W 4 speed meat grinder plastic vertical Blender

Desktop button two color 2 in 1Blender

1.5L 300W multi color custom pink two in one Blender

2 in 1 Metal Cup White Blender

1.5L 250W Metal Grinding Cup White Black Blender

3 in 1 LED Metal Glass Blender

1.5L 300W LED Light Strip Stainless Steel Glass Blender

All metal coffee LED 3 in 1 Blender

1.5L 300W LED Light Strip steel vertical handheld Bledner

All metal kitchen 3 in 1 Blender

1.5L 300W Juice extractor with grinding cup high quality fruit Blender

Ice breaking glass knob Blender

1.5L 500W high power multi function ice cube Blender

LED ice breaker stainless steel glass Blender

1.5L 600W electric LED multi speed Blender

Metal ice breaker three in one Blender

1.5L 500W LED Light Strip stainless steel ice breaker Blender

New large capacity small size Blender

1.8L 250W 110V 3 gears multi function powerful Blender

Glass EK ONE Blender

1.75L 1200W high power EK ONE glass Grey Blender

Knob EK ONE Blender

1.75L 1200W 220V EK ONE Silver Glass Manual Blender

Silent glass heating Blende

1.4L 1200W Korean soundproof glass heating Blende

High borosilicate glass silent touch Blende

1.4L 1200W vertical silent touch digital White Blender

Why choose Sinreen as your China Blender factory?

As a blender manufacturer, SINREEN is undoubtedly the top choice for small appliance brands. SINREEN has been deeply engaged in the blender manufacturing industry for over 10 years, amassing rich experience. Meanwhile, it has had export qualifications for more than 8 years. Its products have been exported to over 100+ countries, demonstrating a profound understanding of the global market.

For regular blender orders, we usually complete delivery within 30 natural days after receiving the advance payment. We can create a customized blender for you. The customization details include the LOGO on the blender, simple usage instructions, outer box/color box design, manual, and warranty card.

All blenders produced by SINREEN have passed a series of strict certifications such as CE, RoHS, and CB. All you need to do is send us an inquiry, and we will provide the most professional service.

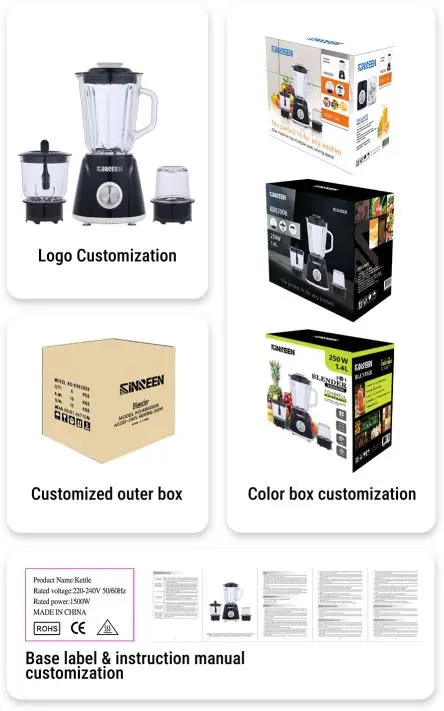

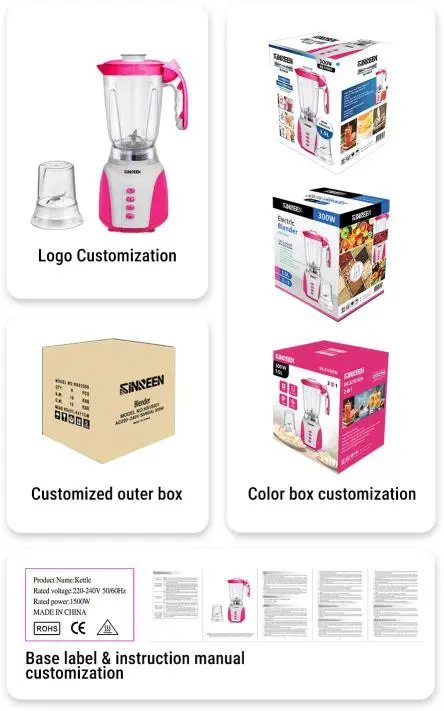

Start customizing your branded Blender

With more than 10 years of experience in custom production, SINREEN can complete all aspects from product design to brand packaging and blender manufacturing, and we support all brand customization projects.

LOGO customization on Blender

Personalized design can be conducted for blenders based on brand requirements. This encompasses silk screen printing, pad printing, laser engraving, thermal transfer, labeling and other printing techniques, making your blender brand more distinctive in the market.

Blender outer box/color box style customization

The outer box and color box styles of the blender can be customized according to your brand image and market positioning. This can effectively enhance the packaging grade of the product. We will carefully design the outer box and color box to perfectly match your brand style in appearance. Whether it’s color matching, pattern design, or material selection, everything will be aimed at presenting brand features and attracting consumers’ attention.

Blender instruction manual and warranty card customization

We will not only provide detailed product information and instructions for blenders but also integrate your brand’s distinctive elements. Through carefully designed manuals and warranty cards, users can not only understand the blender but also deeply sense the unique charm and professional image of your brand, further enhancing users’ awareness and preference for the brand.

Blender brand exclusive recipe website design customization

Create a wealth of usage tips and care methods for blenders for users. Here, users can explore the proper ways of using and maintaining blenders and easily master relevant skills. This exclusive website for blender information will greatly enhance users’ stickiness to your brand, allowing users to be closely connected with your brand while learning about blenders, and start a convenient journey together.

You are at the Most Professional Blender Manufacturer and Supplier – China Factory

We are waiting for you at every Canton Fair

Hope these Blender FAQs can help you

What is the voltage of the Blender power plug?

The voltage of the Blender power plug may be different in different regions. Normally, in most countries and regions, the common Blender power plug voltage is 220V or 110V.

The specific situation will be based on your region. When ordering, we will remind you to choose the voltage that meets your needs. Please note that different voltages will result in different power of different products. For example, 220V is 600W for the product, and 110V is 350W for the product.

When you see that the parameter page of the SINREEN factory Blender pot only has 220V marked, please rest assured that all the Blenders we produce can be changed to 110V.

If you don't know your country, please contact SINREEN for help, or click here for the country plug and voltage situation we have sorted out. We have served the voltages of all countries.

If the wrong voltage is selected, the Blender will burn out the circuit board during use. If the voltage is unstable and too low, the motor speed will not reach the rated speed. At this time, the blade cannot generate enough centrifugal force to effectively crush the ingredients. When the voltage is too high, although the motor speed may increase, this may cause the motor overheat protection device to start. Stable voltage is good for extending the life of Blender.

If you need to customize the voltage, please tell us the actual voltage situation in your area, and we will make special customization in terms of safety and stability.

Here is a list of all the plugs and voltages that SINREEN has served.

Can I customize Blender for my country's voltage?

Of course. SINREEN has more than 10 years of experience in Blender production and more than 8 years of export experience. We have a team of engineers who have been deeply involved in the Blender field for more than 10 years and can meet your customized needs. The Blenders we produce have been exported to more than 100 countries, and we have rich experience in the conditions of different countries.

Experience plays a vital role. For example, in the countries and regions we have served, there is voltage instability. Our engineering team proposed a solution to add a voltage stabilizer, which only added a little cost, but created a huge selling point and business opportunity. Now, we have been working together for 4 years.

As a brand owner and wholesaler, if you want to root your brand in your region, please rest assured that the stability and safety of the product are the top priority. SINREEN will provide you with reliable protection. Our engineering team will develop the best solution for you according to the actual conditions of different regions.

We attach great importance to the stability and safety of our products and have established a strict quality control system. Each Blender undergoes multiple testing processes to ensure that it meets international safety standards. With many years of production and export experience, our Blender has won wide acclaim in many countries and regions around the world. Many customers have given high praise to our product quality and service.

Please rest assured to hand over your products to SINREEN, we will create the best quality Blender for you and help your brand flourish in the market.

What types of Blender do you offer?

Blender types can be divided into many situations

1. Body material

1.1 Plastic ABS injection molding body Blender

1.2 Stainless steel stamping body Blender

2. Motor classification

2.1 250-350W Blender

2.2 350-500W Blender

2.3 500-1500W Blender

3. Function classification

3.1 Is there an ice breaking button Blender

3.2 Does it have a heating function Blender

4. Operation method

4.1 Button operation Blender

4.2 Knob operation Blender

4.3 Touch operation Blender

5. Accessories

5.1 Coffee cup Blender

5.2 Grinding cup Blender

5.3 Minced meat cup Blender

6. Classification of blending cups

6.1 Glass blending cup Blender

6.2 Stainless steel blending cup Blender

6.3 Plastic blending cup Blender

What materials do you use for Blender?

The composition of Blender is mainly divided into several parts, the mixing cup body, circuit board, control button, matching small cup body, Blender host, stirring rod

The main materials of the mixing cup body are as follows:

1. High borosilicate glass:

Advantages: This is the mainstream material of the mixing cup of products such as wall breakers on the market. It has good high temperature resistance, can effectively resist high temperature, can withstand high temperature heating process without breaking, and can generally withstand high temperature of about 108 degrees Celsius; high strength and hardness, can adapt to the impact force generated by high-speed mixing of the wall breakers; high transparency, convenient for users to observe the mixing process of ingredients; stable chemical properties, not easy to react chemically with ingredients, will not release harmful substances, safe and reliable to use.

Disadvantages: The cost is relatively high, and the glass material is fragile, so it needs to be handled with care during use and transportation.

2. Food-grade plastic:

Common materials such as tritan:

Advantages: It has high strength and impact resistance, not easy to break; light weight, easy to operate and carry; good transparency, easy to observe. This material has passed the US FDA certification and has high safety.

Disadvantages: There may be a certain degree of deformation in a long-term high temperature environment, but it is safe and reliable within the normal use temperature range. It is usually used to make blending cups that do not require heating or the heating temperature is not high, such as some blending cups for making juice and cold drinks.

3. Stainless steel:

Advantages: Stainless steel has excellent corrosion resistance and is not easy to rust; it has high strength, is sturdy and durable, and can withstand large external impacts; it is easy to clean and not easy to leave stains.

Disadvantages: The stainless steel cup body is opaque and the mixing of the internal ingredients cannot be observed; it has good thermal conductivity, which may cause the surface temperature of the cup body to be high when mixing hot drinks, and it is necessary to pay attention to prevent scalding; long-term use may cause oxidation of food materials. Generally, stainless steel blending cups are often used in dry grinding and other scenes that do not require heating and have high mixing intensity requirements, and can be used as dry grinding cups.

Main materials of control buttons

The main styles and materials of blender control buttons are as follows:

1. Style:

Round button: This is a more common style with simple operation. Usually, the corresponding functions can be realized by pressing it, such as turning on, off, switching modes, etc. Some round buttons may also have indicator lights to facilitate users to understand the working status of the blender.

Piano-key buttons: This style of button is similar to the keys of a piano, and usually has multiple independent buttons that can control different functions or gears. For example, some blenders have multiple piano-key buttons, corresponding to different blending speeds, time settings and other functions.

Knob-type buttons: The speed and time of blending can be adjusted by rotation. It has the characteristics of continuous adjustment, good operating feel, and can be set more accurately according to actual needs. Generally speaking, there will be scale marks on the knob-type buttons to facilitate users to master the degree of adjustment.

Touch buttons: It is a relatively new control method that is operated by touch sensing. The appearance of touch buttons is usually simple, the surface is flat, and they are waterproof and dustproof, and they are also easy to clean. However, touch buttons may not be as obvious as physical buttons in terms of operational feel feedback.

Square buttons: The square appearance design matches the overall shape of the blender and has a certain aesthetic appeal. Its function is similar to that of the round button, and the corresponding operation can be achieved by pressing it.

Pull-string buttons: Mainly used in some special occasions or specific types of blenders, such as large industrial blenders. When an emergency occurs, the mixer can be stopped immediately by pulling the pull cord, which plays a role in safety protection.

2. Material:

Plastic: One of the common button materials, it has the advantages of low cost, light weight, and good insulation. For example, ABS plastic has high strength and toughness and is often used to make button shells; polycarbonate plastic has good transparency and heat resistance and can be used to make button covers with indicator lights, etc. However, the wear resistance and aging resistance of plastic materials are relatively poor, and long-term use may cause wear or discoloration.

Metal: Metal materials such as stainless steel and aluminum alloy have high strength and wear resistance, can withstand large pressing force, and have a long service life. The appearance texture of metal buttons is good, giving people a high-end and durable feeling. However, the cost of metal materials is high and may be conductive. If the working environment of the mixer is relatively humid, it is necessary to take good insulation measures.

Rubber: Rubber buttons have good elasticity and anti-slip properties, moderate pressing force, and comfortable feel. On some mixers that require frequent operation, rubber buttons can reduce user hand fatigue. In addition, rubber also has certain waterproof and dustproof properties, which can protect the electronic components inside the button.

What small cups are usually equipped with blenders?

1. Grinding cup

Purpose: Used to grind dry materials such as coffee beans, nuts, grains, etc. It can grind these ingredients into fine powder, which is convenient for making coffee, nut butter, grain powder, etc. For example, when you want to make a fresh cup of coffee, you can put the coffee beans into the grinding cup and grind them into coffee powder suitable for brewing through the high-speed operation of the blender.

Features: The material of the grinding cup is generally strong, the cup wall is thick, and it can withstand the greater impact force generated during the grinding process. The blade inside is usually designed as a blunt knife, which grinds the ingredients through strong impact and friction, rather than using sharp cutting blades like a blender.

2. Minced meat cup

Purpose: Specially used for mincing meat ingredients, such as pork, beef, chicken, etc. It can be used to make meat fillings for dumplings, buns, or to make meat patties, meatballs and other delicacies. For example, when making handmade dumplings, you can quickly get a uniform and delicate meat filling by putting fresh pork into the minced meat cup.

Features: The blade of the minced meat cup is generally sharp and can effectively cut meat fibers. And the capacity of the cup body usually has multiple specifications to meet the needs of different users. The small one can mince a small amount of meat for personal meals, and the large one can handle more meat for family gatherings and other occasions.

3. Supplementary food cup

Purpose: Mainly used to make complementary food for infants and young children. Vegetables, fruits, meat and other ingredients can be mixed and stirred to make delicate pureed complementary food, such as carrot puree, apple puree, chicken puree, etc. This is very convenient for feeding babies because it can mix different ingredients in appropriate proportions to ensure that the baby can take in a variety of nutrients.

Features: The material of the supplementary food cup is usually food-grade safe material, such as food-grade plastic or high borosilicate glass. Its capacity is generally small because the baby eats relatively little each time. Moreover, the stirring effect of the supplementary food cup should be more delicate, and the ingredients can be stirred into a very delicate state, which is convenient for the baby to swallow.

4. Measuring cup

Purpose: Used to accurately measure the volume of ingredients. In the cooking process, accurate amount of ingredients is one of the keys to making delicious dishes. Measuring cups can help users measure the volume of liquid ingredients (such as milk, water, etc.) and some granular ingredients (such as rice, flour, etc.). For example, when making bread, it is necessary to accurately measure the amount of flour and water, and measuring cups can play a good role.

Features: Measuring cups usually have scale marks, and the scales are clear and accurate. The material is generally transparent plastic or glass, which is convenient for observing the volume of ingredients. Its shape design is also relatively reasonable, which is convenient for holding and pouring ingredients.

1. Motor

Composition and function: The motor is the core power component of the Blender host. It is responsible for driving the blade to rotate at high speed, thereby realizing functions such as mixing and crushing. The motor is mainly composed of a stator and a rotor. The stator is the stationary part of the motor, which generates a magnetic field; the rotor is the rotating part of the motor, which rotates under the action of the magnetic field.

Material: The motor casing is generally made of metal, such as aluminum alloy or cast iron. The aluminum alloy casing has the characteristics of light weight and good heat dissipation; the cast iron casing is more solid and can withstand greater pressure and vibration. The winding inside the motor is usually made of copper wire. Copper has good conductivity, which can reduce power loss and improve the efficiency of the motor.

2. Base

Composition and function: The base is the part that supports the entire Blender host. It also plays the role of fixing the motor, circuit board and other components. At the same time, there may be some shock absorbers inside the base to reduce the vibration and noise generated when the motor is running.

Material: The base is commonly made of plastic and metal. Plastic bases (such as ABS plastic) are low-cost, light-weight, and can be molded into various shapes. Metal bases (such as stainless steel or aluminum alloy) are more durable and have a better appearance and texture. They are usually used in mid-to-high-end Blender products. Some bases also use composite materials, such as wrapping a metal shell on the outer layer of the plastic base to combine the advantages of both.

3. Circuit board

Composition and function: The circuit board is a key component for controlling the work of Blender. Various electronic components such as chips, capacitors, resistors, transistors, etc. are integrated on it. The chip is used to control the speed and timing of the motor; the capacitor and resistor play the role of filtering and voltage stabilization to ensure the stable operation of the circuit. Through the circuit board, users can operate various functions of Blender, such as starting, stopping, adjusting speed, etc.

Material: The circuit board is mainly made of materials such as glass fiber and epoxy resin. Glass fiber provides the basic structural strength of the circuit board, and epoxy resin plays the role of insulation and fixing electronic components. The shell materials of electronic components on the circuit board are different. For example, chips are generally ceramic or plastic packages. There are many types of capacitors, such as ceramic capacitors and electrolytic capacitors. The shell material also varies depending on the type of capacitor.

4. Shell

Composition and function: The shell mainly protects internal components and beautifies the appearance of the product. It can prevent dust, moisture, etc. from entering the host, and at the same time make Blender more attractive in appearance and meet the aesthetic needs of users.

Material: The shell is usually made of plastic and metal. Plastic shells (such as polycarbonate) have the advantages of low cost, easy processing and molding, and a variety of colors. Metal shells (such as stainless steel or aluminum alloy) are more solid, have a good texture, and have good heat dissipation performance, but the cost is relatively high. Some high-end Blender products may use a shell design that combines metal and plastic, such as using metal in key parts to enhance strength and using plastic in other parts to reduce costs.

5. Shaft and blade connection parts

Composition and function: The shaft is the part that connects the motor and the blade. It transmits the power of the motor to the blade, allowing the blade to rotate at high speed. The blade connection part is used to fix the blade to ensure the stability and safety of the blade during rotation.

Material: The shaft is generally made of metal, such as stainless steel or alloy steel. These metal materials have high strength and toughness and can withstand the torque generated when the blade rotates at high speed. The blade connection part is usually also made of metal, and may use special connection methods (such as screw fixing, slot fixing, etc.) to ensure a firm connection between the blade and the shaft.

How do the Blender manufacturers control quality?

Quality is the lifeblood of a brand's long-term operation. This is not only our unswerving goal, but also what you are eagerly looking forward to. We deeply understand that only high-quality products can gain the trust of customers and win the recognition of the market.

Take our Blender production in 2023 as an example. The defective rate is only 2‰, which means that for every 1,000 Blenders produced, there are only two defective products. This achievement is the result of our continuous optimization of production lines and improvement of production methods. In a market environment as competitive as a battlefield, it is not easy to control the defective rate so low. Behind it is the R&D team's day and night research and iron-fisted control of each production link.

Generally speaking, when processing large orders, we will prepare for customers 5‰ of the accessories are used as spare parts. Moreover, once defective products appear, we will promptly reissue them in the next batch of orders. But this is by no means our ultimate pursuit. We will continue to strive for higher quality standards.

Our quality inspection is divided into two parts: immediate inspection after the production line is completed and spot inspection before shipment. After the production line is completed, the quality inspectors will conduct a comprehensive inspection of each Blender in accordance with strict quality standards, from appearance to function, to safety, without omission. The spot inspection before shipment is the pursuit of perfection, and it is imperative to ensure that the products delivered to customers are high-quality products. These are our hard work to control quality.

In addition, we will also teach you maintenance experience. Through detailed maintenance guides, vivid online video tutorials and other channels, customers can quickly solve problems when they encounter them, minimizing the troubles caused by failures. We firmly believe that only by providing comprehensive quality assurance can customers rest assured and create a long-term brand glory with us.

What warranty conditions does the Blender manufacturer offer?

1. Accessories provision

We will provide 5‰ accessories for each batch of goods, and reissue the quality problem products in the next batch of orders.

2. Basic warranty period

Generally, Blender products are provided with a one-year quality warranty. Within this year, if the product has quality problems that are not caused by human damage, the manufacturer will be responsible for repairing or replacing the problematic parts.

3. Extended warranty negotiation

If the brand needs a longer warranty, it can communicate and negotiate with the manufacturer's engineers. Some more durable accessories may be replaced according to the specific situation, but this is not absolute and may increase additional costs.

4. Durability test

Our conventional products will undergo long-term durability tests in the early stage of the mold, and generally they will be tested for 700 hours to confirm the stability of the product.

What new technologies are available from the makers of Blender?

Intelligent control system:

Convenient operation: Equipped with advanced intelligent control system, users can easily select different mixing modes, adjust speed and time, etc. through touch screen or mobile phone application. The operation is simple and intuitive, allowing users to quickly get started.

Personalized settings: It can achieve personalized mixing effects according to user needs. Whether it is juicing, crushing ice or mixing multiple ingredients, it can provide precise mixing, unleash users' creativity and try more delicious drink combinations.

Intelligent sensing technology:

Safety monitoring: It has devices such as intelligent gravity sensors, which can detect whether the mixing cup is firmly installed or whether there are abnormal conditions such as tilting. If there are abnormalities, it will automatically stop working to avoid accidents and ensure the safety of users.

Overload protection: When the machine load is too high, it will automatically stop working to prevent the machine from being damaged due to overload, extend the service life of the machine, and also ensure the safety of users.

Intelligent nutritional analysis:

Accurate calculation: Equipped with an intelligent nutritional analysis system, it can accurately calculate the calories, vitamin content and other nutritional components of each cup of drink. Users only need to enter the used By providing information such as the type and weight of fruits used, users can instantly obtain a detailed nutritional analysis report, helping users better understand their dietary intake and meet modern people's pursuit of healthy eating.

Intelligent maintenance reminder:

Timely feedback: The machine can intelligently remind users to perform maintenance such as cleaning and replacing parts based on factors such as usage time and operating status to ensure that the machine always maintains a good operating condition. And it will inform users of specific maintenance items and time, so that users can manage and maintain equipment more scientifically.

High-performance motor technology:

Powerful power: A more powerful motor has been developed to quickly and easily stir hard and tough ingredients such as crushed ice and grains. The powerful motor not only improves the stirring efficiency, but also makes the machine run more stably and durable, meeting users' needs for efficient stirring.

Multi-function blade technology:

Multiple functions in one: The introduction of a multi-function blade can achieve multiple functions such as stirring, mashing, mixing, cutting, etc., helping users to easily prepare different dishes and drinks, meet diverse cooking needs, and reduce users' dependence on multiple kitchen tools.

How to customize Blender?

We have been engaged in ODM/OEM customized production of Blender for more than 10 years. It is no exaggeration to say that SINREEN is one of the top Blender OEM factories in China.

With more than 10 years of customized production experience, we have provided high-quality Blender customization services to a large number of well-known domestic and foreign brands, and have been widely praised by customers. We not only have advanced production equipment, but also a strict quality control system to ensure that each Blender meets international standards. At the same time, our R&D team continues to innovate to create the most competitive customized solutions for customers.

Generally speaking, our customization projects include:

Blender LOGO customization: Carry out personalized design according to customer needs to make your brand stand out in the market.

Blender's simple food cooking plan customization: carefully prepared by a team of professional nutritionists to provide users with healthy and delicious cooking guides.

Blender outer box/color box style customization: tailored to your brand image and market positioning to improve the quality of product packaging.

Blender Customized manuals and warranty cards: can present detailed product information and instructions for use, and can also highlight your brand characteristics.

Brand-exclusive recipe website design for Blender recipes: provide users with a rich variety of blending and juicing recipes to enhance user loyalty to your brand.

Whether you are a brand owner or a wholesaler, we can provide you with professional Blender customization services to meet your personalized needs. Let us work together to create high-quality Blender products, expand the market, and create brilliance.

How to choose the best Blender factory in China?

Things to note when choosing a Blender manufacturer in China as your brand OEM

1. Does the selected Blender factory have export experience?

2. Does the selected Blender factory have more than 3 production lines?

3. Does the selected Blender factory have its own warranty policy?

4. Has the selected Blender factory participated in international exhibitions?

5. Does the selected Blender factory update the style every month?

6. Does the selected Blender factory have more than 3 upstream suppliers?

Will the Blender manufacturer in China help ship Blender?

We all know that cross-border transportation is not so easy, because it involves taxes between countries, import taxes, value-added tax, consumption tax, etc. At the same time, if you want to get your goods, you need to register with your customs, etc. If you are choosing a factory in China for the first time, SINREEN is undoubtedly your best choice. We have been in the field of Blender export for more than 8 years. During this time, we have exported to more than 100 countries. We almost meet all the countries' import requirements for products and the production of documents required for customs clearance. This is very important. If the documents are not produced up to standard, it is very likely that you will not be able to get your goods smoothly. At the same time, an excellent Chinese factory can ask you to reduce import taxes through suitable documents, of course, this is legal. At the same time, we also connect with large freight forwarders, and we will get a very favorable price in sea transportation, so please rest assured that whether it is your first time to purchase Blender in China, you can always choose SINREEN, which can escort your products.

How long does it take for a Blender manufacturer to deliver a Blender order?

There are many special cases for the delivery time of orders

1. We can ship spot order products at any time.

2. For customized products, we will start purchasing parts from the time you pay the advance payment. Usually, it takes 10 natural days to purchase parts, and then we will start scheduling and preparing for production. We will follow the order of confirmation of existing orders and produce a large sample first. After the sample is tested and communicated, formal production will begin. Generally, each production line of SINREEN can produce a 40HQ order every day. After your advance payment is received, we usually complete the confirmation of the large sample and the formal order production within 30 natural days.

What are the recommended quality standards for Blender?

United States:

ASTM standards: The relevant standards of the American Society for Testing and Materials (ASTM) will involve blenders. For example, the ASTM F1568-08 standard is used for commercial food blenders and specifies the material, performance and other requirements of the product.

UL standards: Underwriters Laboratories (UL) standards have a regulatory effect on blenders on the US market. For example, UL 197 is used for commercial electric blenders with a rated voltage of 600 volts or less, and UL 763 is used for commercial motor-driven blenders.

Europe:

CE certification: In Europe, the CE mark is a necessary certification for electrical products such as blenders to circulate in the EU market. Blenders need to comply with EN60335-1:2012+A11 (safety requirements for household and similar electrical appliances), EN60335-2-14 (safety requirements for specific electrical appliances, mainly focusing on the safety performance of kitchen equipment and kitchen machinery), EN55014-1 (electromagnetic compatibility), EN62233 (measurement methods for electromagnetic radiation generated by electrical and electronic equipment), EN55014-2 (radiation, radiation resistance requirements and test methods for household and similar electrical equipment), etc. In addition, they must also meet the corresponding requirements in terms of mechanical safety performance, materials and chemicals, electrical safety, acoustic performance, packaging and labeling.

Australia:

SAA certification: The SAA certification of the Australian Standards Committee is an important certification for blenders to enter the Australian market. The certification process includes multiple tests such as electrical performance testing, mechanical performance testing, and safety performance testing to ensure that the blender meets relevant standards.

Singapore:

CB Certification: Blenders must follow the safety standards set by the International Electrotechnical Commission (IEC), such as the IEC60335 standard, to apply for CB certification in Singapore. CB certification is a comprehensive certification process that helps blender products enter the Singapore market and prove that they comply with international safety standards.

Japan:

PSE Certification: Japan's electrical product safety certification system. If blenders are sold in the Japanese market, they need to meet the requirements of PSE certification. There are strict testing and evaluation standards for electrical safety, mechanical safety, material safety, etc. of blenders to ensure that the products comply with Japanese safety regulations.

JIS Standards: There may be standards related to blenders in the Japanese Industrial Standards (JIS), which stipulate the requirements for the performance, structure, materials, safety, etc. of blenders. For example, there will be specific indicator requirements in terms of mixing efficiency, noise level, durability, etc.

South Korea:

KC Certification: South Korea's mandatory certification system. Blenders need to pass KC certification to enter the Korean market. The certification process includes testing and evaluation of product safety, electromagnetic compatibility, etc. Only blenders that have obtained KC certification can be legally sold in the Korean market.

Germany:

GS certification: Although GS certification is not mandatory, it has a high degree of recognition in the German market. For blenders, obtaining GS certification means that the product has reached high standards in terms of safety, quality and performance. The requirements of GS certification are usually more stringent than the EU's CE certification. In addition to meeting basic safety requirements, the product's reliability, durability and other aspects are also tested.

Canada:

CSA certification: The certification of the Canadian Standards Association (CSA) is one of the important certifications for blenders to enter the Canadian market. CSA certification tests and evaluates the electrical safety, mechanical safety, fire protection and other aspects of blenders to ensure that the product meets Canadian safety standards.

cUL certification: If the blender is designed and produced in accordance with the US UL standard, it may be necessary to obtain cUL certification in the Canadian market to prove that it meets Canadian safety requirements.

Brazil:

INMETRO certification: Brazil's National Institute of Metrology, Standardization and Industrial Quality (INMETRO) is responsible for formulating and implementing Brazil's product certification system. Blenders sold in the Brazilian market need to obtain INMETRO certification, and the certification process includes testing and evaluation of product safety, performance, environmental protection, etc.

India:

BIS certification: Certification by the Bureau of Indian Standards (BIS) is very important for electrical products sold in the Indian market. Blenders need to meet the relevant safety, performance and other standard requirements set by BIS, including electrical safety, mechanical structure safety, material reliability, etc. For example, there may be specific regulations and testing requirements for the motor performance, mixing efficiency, noise level, heat resistance and impact resistance of the shell material of the blender.

Russia:

GOST certification: Russia's GOST certification is a necessary certification for products to enter the Russian market. For blenders, it is necessary to comply with relevant Russian technical regulations and standards, involving requirements in electrical safety, mechanical safety, electromagnetic compatibility, etc. In addition, the product's logo, instructions, etc. also need to comply with relevant Russian regulations.

UK:

Although there have been some changes in standards and certification systems after Brexit, electrical products such as blenders still need to meet the corresponding safety and quality standards. In addition to following some basic requirements of the EU CE certification, the UK may have some specific requirements and standards for its own market, such as more stringent testing and evaluation in terms of product reliability and durability.

Italy:

Italy has its own quality standards and certification system, and blenders sold in the Italian market need to meet relevant standards and requirements. These requirements may involve product design, manufacturing, performance, safety and other aspects to ensure consumer safety and product quality. For example, there may be specific regulations for the blade material, rotation speed, material and sealing of the blender.

Saudi Arabia:

SASO certification: Certification by the Saudi Arabian Standards Organization (SASO) is the key to product entry into the Saudi market. Blenders need to pass SASO certification, including evaluation and testing of product safety, energy efficiency, environmental protection and other aspects. For example, there are strict requirements for the electrical insulation performance, overheating protection device, and environmental protection of materials of blenders to adapt to the local climate and use environment in Saudi Arabia.

UAE:

ECAS certification: The UAE Conformity Assessment Scheme (ECAS) certification is required for products entering the UAE market. The mixer needs to meet the relevant standards and requirements of ECAS, including product safety, performance, reliability, etc. During the certification process, the electrical safety, mechanical safety, electromagnetic compatibility, etc. of the mixer will be tested and evaluated to ensure that the product meets the market access standards of the UAE.

Turkey:

TSE certification: The certification of the Turkish Standards Institute (TSE) is an important basis for the sale of products in the Turkish market. The mixer needs to be certified by TSE to prove that it meets the relevant standards and requirements of Turkey, including product quality, safety, performance, etc. For example, there may be specific standards and testing requirements for the motor power, mixing effect, noise level, etc. of the mixer.

How do you support OEM Blender designs?

OEM is the abbreviation of Original Equipment Manufacturer, which means "Original Equipment Manufacturer" in Chinese. OEM usually refers to a company producing products according to the requirements of another company, and the products are sold under the brand of the entrusted company.

OEMBlender means that the brand owner entrusts the production of Blender to a professional upper manufacturer such as (SINREEN). There are usually two modes.

The first one: the entrusting party is usually responsible for the design, research and development, marketing and sales of the product, while the OEM manufacturer focuses on manufacturing according to the requirements of the entrusting party.

The second one: the entrusting party selects the style from the Blender manufacturer, and the OEM manufacturer manufactures according to the requirements and selected style of the entrusting party.

SINREEN can complete all links from product design to brand packaging and Blender manufacturing. We support all customized projects such as LOGO printing, product outer box/color box, manual/warranty card, recipe website customization. For specific details, please contact our sales staff, and you will get the most complete OEMBlender customization manual.

Where are the best Chinese Blender manufacturers?

In China, the main industries of Blender are Guangdong Province and Zhejiang Province, and the cities are Zhongshan City, Ningbo City, and other regions.

Guangdong Region:

Industrial Advantages: Guangdong is an important home appliance manufacturing base in China. It has industrial cluster advantages in blender production, a complete industrial chain, and complete supporting links such as raw material supply, parts processing, and product assembly, which can effectively reduce production costs and improve production efficiency. In addition, Guangdong has a developed economy and convenient transportation, which is convenient for the transportation and sales of products and has a wide market coverage.

Zhejiang Region:

Industrial Advantages: Zhejiang's small home appliance industry has developed rapidly and has strong strength in the field of blender manufacturing. The region has many small home appliance manufacturing companies, and the competition is fierce, which prompts companies to continuously improve product quality and innovation capabilities. At the same time, Zhejiang has a good manufacturing foundation and a rich reserve of technical talents, which provides strong technical support for blender manufacturing.

Can I get samples from the Blender manufacturers before buying?

I believe that your needs will be met in any Blender factory. In SINREEN's view, Blender samples are indispensable. In order to avoid cognitive bias and prevent special circumstances when producing large quantities of goods, samples are of paramount importance.

For samples, we usually divide them into three situations.

The first one is to confirm whether the product is ordered and need to conduct product quality testing. You can consult our sales staff. We will recommend you a Blender suitable for sales in your area according to your situation, and we will also provide you with free samples if it is suitable for you.

The second is that when you order a container or a batch order, we will create a pre-production Blender sample for you before the production order starts. We can communicate remotely or send you samples, depending on your requirements. When there is a problem with the sample, we will adjust it according to the situation to meet your requirements.

The third is to change the test samples of some core components. For example, our sample template is a 220V Blender, and now it needs to be changed to 110V. The original Blender has a knob and needs to be changed to a touch button. These are all core component sample changes, which may cause changes in the product and the original parameters. This kind of sample usually takes 10-20 working days to start production.

Why choose SINREEN as your Blender manufacturer?

If you only need one Blender, we recommend you to choose your local brand Blender or world brand Blender products.

If you need to wholesale and customize your brand Blender for your business, SINREEN is undoubtedly one of your best choices. SINREEN has more than 10 years of experience in the Blender field. We have full experience in Blender. Whether it is R&D, production, or market, we will give you the best advice. At the same time, I have exclusive solutions for different types of customers, such as wholesalers' mix and match of 100/200 units of each model, such as brand owners' customization of a whole set of brands, and traders' overall matching of kitchen appliances. We have full experience. Please feel free to contact SINREEN. Here you will definitely find the most suitable solution and achieve a win-win situation with us.

How do I protect my custom Blender designs?

We are well aware that your protection of Blender's design is of great significance, which fully reflects our respect for intellectual property rights.

Under normal circumstances, your order will have the following situations:

First, if Blender's product design chooses Sinreen's style, the product box can be jointly designed by your designer and us, or it can be designed entirely by your designer. In this case, you have the right to retain the design of the product box for 1 to 3 years. During this period, we will strictly keep the design secret and never disclose it to other brands.

Second, when Blender's product design is completed by you and the product mold fee is borne by you or shared with Sinreen, the product will become an exclusive product. We will not produce for any other customers unless authorized by you. If customers in other regions want to buy, we will contact you and pay the licensing fee to you.

Third, if Blender's product design chooses Sinreen's style and you want to sell it exclusively, then please rest assured that there will be no additional fees. At this time, the exclusive sales range can be divided into provinces, countries, continents or the whole world, which will be determined according to your order volume.

What are SINREENBlender's payment terms?

For payment terms, we accept a variety of conventional payments, T/T, Paypal, Alibaba, L/C and other common payment terms.

For special cases, we also support payment upon seeing the bill of lading.

Normally, we accept 30% T/T payment and the remaining 70% needs to be settled before we ship, or L/C at sight and other terms.

For small sample fees, Paypal and Alibaba are usually easier.

For currency, we support US dollars, euros, pounds, and other 9 common currencies, and RMB payment. Of course, if you want to learn more about more payment options, we have been engaged in the field of foreign trade for 8 years and support almost all payment methods. You can contact our sales for support

Do you offer stock Blender?

As a Blender manufacturer, we usually prepare 3 to 5 hot-selling products in stock, mainly for small-scale wholesalers and customers who order 100 to 500 units each time. Usually, this kind of stock products do not have LOGO, and the color box is neutral packaging. If you need to print your own LOGO, we have a variety of solutions, such as crystal stickers and screen printing, but this may incur some fees. For most product models, we generally do not prepare stocks, but we have more than 10 Blender production lines, please rest assured of our delivery speed.

If you need to order our stock Blender, please contact our sales in advance, and they will send you our stock list.

Brands that cooperate with Sinreen

SINREEN Blender Factory