In the modern catering industry and home kitchens, multi-functional meat grinders have become an indispensable kitchen tool. It not only improves the efficiency of meat processing, but also enables a variety of cooking possibilities, bringing great convenience to chefs and housewives. Today, let us walk into a factory that specializes in manufacturing multi-functional meat grinders, learn about the production process of this magical equipment, and experience the unlimited cooking possibilities.

Ⅰ. Design concept of excellence

The design concept of this multifunctional meat grinder stems from in-depth research on cooking needs. Our designers adhere to the principle of excellence and continuously optimize the product structure to provide higher performance and more convenient operating experience. While ensuring powerful functions, we also pay attention to the appearance design to make the meat grinder more modern and complement the kitchen environment.

Ⅱ. Rigorous production process

Material selection:

We strictly control material selection and only use high-quality steel to ensure the durability and stability of the equipment. At the same time, according to different parts, we select appropriate materials to meet their needs in terms of wear resistance and corrosion resistance.

Casting:

Advanced casting technology is used to ensure the dimensional accuracy and surface quality of parts. During the casting process, we strictly control the molten iron composition and cooling rate to reduce internal stress and pores and improve the strength and toughness of parts.

Machining:

We use high-precision CNC equipment for machining to ensure the dimensional and shape accuracy of the parts. During the processing, we strictly control the processing parameters to ensure the surface quality and roughness of the parts.

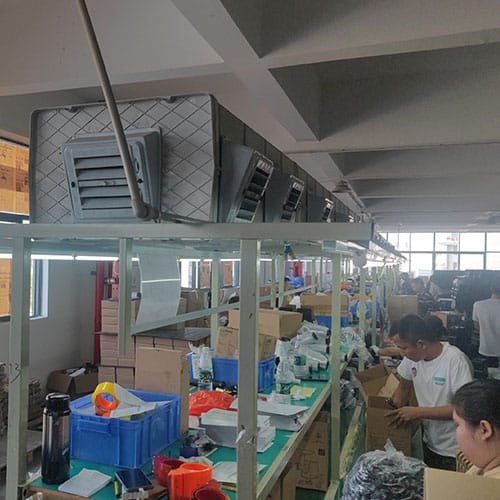

Assembly:

In the assembly process, we use professional assembly processes and equipment to ensure the matching accuracy of parts.

At the same time, we pay attention to the lubrication and sealing of parts to improve the operating efficiency and service life of the equipment.

Quality inspection:

We have a strict quality inspection process.

From raw materials to finished products, every step is carefully inspected. We use advanced testing equipment and technology to ensure that the quality of each multi-function meat grinder meets standard requirements.

Packaging and transportation:

We use professional packaging materials and methods to ensure that the equipment is not damaged during transportation. At the same time, we reasonably arrange transportation routes and times to ensure that the equipment can be delivered to customers on time.

Ⅲ. Diversified product functions

This versatile meat grinder is packed with features to meet a variety of cooking needs. Whether it’s tender meat fillings, delicious meatballs, or even creative meat products, it can be done easily. In addition, it can also be used for vegetable processing, such as shredding, slicing, etc., making cooking easier and more fun.

Ⅳ.Perfect after-sales service

We know that after-sales service is an important guarantee for the long-term development of an enterprise. Therefore, we provide comprehensive after-sales services, including equipment installation, usage training, regular maintenance, etc.

We have also set up a dedicated customer service hotline to answer any questions customers encounter during use.

In short, visiting the production process of this multifunctional meat grinder gave us a deep sense of the unlimited cooking possibilities.

It not only improves cooking efficiency, but also brings great convenience to chefs and housewives. Let’s work together and use this excellent equipment to create more delicious dishes for the world!